Make Best Use Of Performance With Resilient Undercarriage Components

In the realm of hefty equipment and equipment, the function of undercarriage parts is vital in guaranteeing optimum performance and long life. The effectiveness and performance of these elements can substantially influence the general operation of equipment, making the option of resilient undercarriage components a vital decision for operators and supervisors alike. By exploring the complex partnership between sturdiness and efficiency in undercarriage parts, a much deeper understanding of the subject arises, clarifying the crucial elements that drive functional success. As we browse through the complexities of undercarriage maintenance, element, and durability selection, an extensive expedition waits for to introduce the key methods for attaining peak performance in durable applications.

Advantages of Making Use Of Sturdy Undercarriage Components

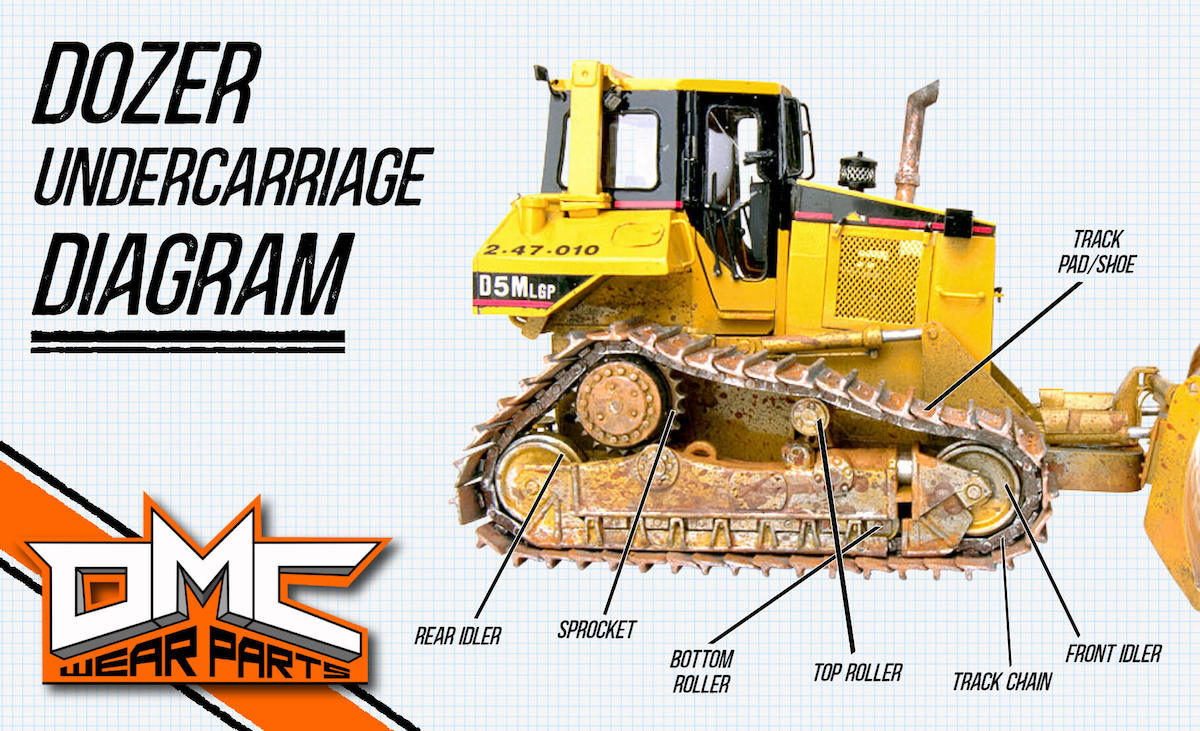

Making use of durable undercarriage components not just boosts the long life of heavy machinery but additionally minimizes upkeep prices dramatically. By buying high-quality undercarriage components, such as tracks, rollers, idlers, and sprockets, devices drivers can experience enhanced uptime and improved overall efficiency.

Furthermore, the durability of hefty machinery is directly linked to the high quality of its undercarriage components. Sturdy components can endure the roughness of requiring applications, ensuring that the devices stays functional for extensive durations. Therefore, drivers can avoid expensive downtime and maintenance costs, eventually taking full advantage of the roi for their equipment.

Aspects Influencing Undercarriage Sturdiness

The toughness of undercarriage components in hefty equipment is affected by numerous critical factors that directly impact performance and longevity. One of the key factors influencing undercarriage durability is the quality of materials used in production. High-grade products, such as hard steel, are necessary for holding up against the severe conditions and hefty loads that undercarriage parts are subjected to. Proper upkeep techniques also play an important duty in determining the life expectancy of undercarriage parts. Normal examinations, lubrication, and prompt replacement of damaged components can substantially extend the resilience of the undercarriage.

Furthermore, ecological elements can have a significant effect on the longevity of undercarriage components. Exposure to rough products, extreme temperatures, and extreme working conditions can speed up wear and tear on undercarriage components. As a result, selecting undercarriage components that are especially developed to hold up against these environmental obstacles is important for ensuring toughness.

Furthermore, the design and design of undercarriage parts have a direct influence on their sturdiness. Parts that are made to disperse loads evenly, minimize rubbing, and decrease stress and anxiety focus are most likely to have a much longer life-span - undercarriage parts. By taking into consideration these crucial elements, equipment operators can make the most of the sturdiness and performance of their undercarriage parts

Upkeep Tips for Lengthening Undercarriage Life

Carrying out regular upkeep routines is essential for expanding the life expectancy of undercarriage elements in hefty equipment. Furthermore, ensure that the undercarriage is appropriately oiled according to producer standards to minimize friction and protect against premature wear.

An additional important upkeep suggestion is to maintain the undercarriage clean from dust, rocks, and debris. Build-up in the undercarriage can speed up wear and deterioration, resulting in pricey repair work. Cleaning the undercarriage after operation in harsh my response problems is recommended to avoid he said these issues.

Finally, monitoring and recording maintenance activities can aid in creating an aggressive maintenance schedule. Maintaining thorough records of substitutes, assessments, and fixings can give valuable understandings right into the undercarriage's condition and performance in time, helping in anticipating and protecting against potential failures. By following these upkeep pointers diligently, operators can dramatically raise the resilience and performance of undercarriage parts in heavy machinery.

Selecting the Right Undercarriage Parts

Selecting ideal undercarriage elements is important for optimizing the efficiency and long life of heavy equipment. When it comes to selecting the ideal undercarriage elements, there are numerous elements to take into consideration.

Furthermore, considering the high quality and reputation of the maker is vital. Going with reliable brand names understood for generating resilient and high-performance undercarriage parts can dramatically influence the general performance and durability of the equipment. Ensuring that the elements are suitable with the equipment version and appropriately installed is important for ideal efficiency. By carefully selecting the best undercarriage elements, tools owners can improve performance, lower downtime, and expand the lifespan of their heavy machinery.

Study: Improved Efficiency With Resilient Components

Integrating sturdy undercarriage parts has actually shown significant enhancements in equipment performance. One instance study entailed a construction business that updated its excavator's undercarriage parts to much more sturdy options.

In one more instance, a mining procedure replaced the undercarriage parts of its excavator with high-quality, resilient choices. This button resulted in an exceptional improvement in the excavator's ability to move and overall performance. The device might browse tough terrains extra successfully, leading to enhanced functional effectiveness and lowered fuel consumption.

Furthermore, a logging their explanation company invested in durable undercarriage parts for its forestry devices. These situation research studies highlight the concrete benefits of making use of resilient undercarriage parts in maximizing machinery efficiency and durability.

Conclusion

In final thought, using durable undercarriage parts can substantially improve performance and long life of hefty machinery. Case researches have shown that investing in resilient undercarriage parts can lead to boosted overall efficiency and efficiency in various industries.

The efficiency and efficiency of these parts can significantly influence the general operation of equipment, making the selection of long lasting undercarriage parts a vital decision for operators and supervisors alike.Integrating sturdy undercarriage components has shown substantial improvements in machinery performance. These case studies highlight the tangible benefits of utilizing resilient undercarriage parts in enhancing machinery performance and durability.

In final thought, utilizing durable undercarriage components can significantly improve performance and durability of heavy machinery (undercarriage parts). Case studies have revealed that spending in long lasting undercarriage components can lead to boosted general performance and performance in numerous markets